Finger joints, also known as box joints or comb joints, are a crucial element in the world of woodworking. These interlocking connections not only enhance the strength and stability of wooden structures but also add an aesthetic touch that elevates the craftsmanship of the finished piece. Understanding the intricacies of finger joints opens the door to more robust woodworking projects, allowing artisans to create pieces that are both functional and visually striking.

At their core, finger joints involve the precise cutting of complementary profiles into the ends of two pieces of wood. The resulting "fingers" interlock, forming a tight connection that can be glued together for added strength. This method is particularly advantageous when working with wider pieces of wood, as it effectively eliminates the weaknesses that come with trying to use a single, wide board. By combining narrower boards, finger joints create a surface that can span greater widths while maintaining structural integrity.

One of the most significant benefits of finger joints is their ability to distribute stress evenly across the joint. This characteristic is particularly valuable in furniture making and cabinetry, where the joints may be subjected to various forces, such as bending or twisting. Traditional joinery techniques, such as butt joints or dowels, often fail under pressure because they do not provide enough surface area for gluing. Finger joints, however, have a much larger gluing surface, making them less prone to separation and more capable of handling heavy loads.

The aesthetic appeal of finger joints cannot be overlooked. When executed with precision, these joints create a visually interesting pattern that highlights the craftsmanship involved in the construction. The interlocking fingers can be left exposed for a modern, industrial look or concealed within the piece for a more traditional finish. Artisans can experiment with different wood species, grain patterns, and finishes to create unique visual effects, allowing each project to stand out.

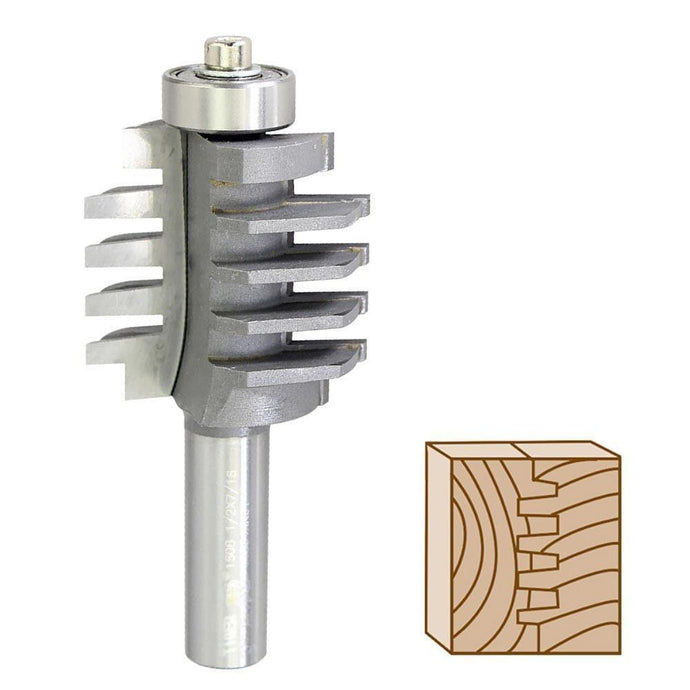

To create finger joints, woodworkers typically use a router or a table saw equipped with a specialized jig. The setup requires careful measurements and adjustments to ensure the fingers fit together perfectly. This precision is critical; even minor discrepancies can lead to loose joints or misalignments that compromise the overall integrity of the piece. As with any woodworking technique, practice is essential. Beginners may find the process challenging at first, but with patience and diligence, they can master the art of finger joint construction.

One common application of finger joints is in drawer construction. The joints provide strength and stability, ensuring that the drawer can withstand regular use without falling apart. This technique is especially favored in high-quality cabinetry, where durability and aesthetics are paramount. Finger joints also work well for boxes, frames, and various other projects where strength and appearance are both crucial.

In addition to their practical applications, finger joints are an integral part of the woodworking lexicon. They are often featured in high-end furniture pieces, showcasing the skill and precision of the craftsman. This type of joinery signals to clients and customers that a piece is crafted with care and attention to detail, often leading to higher perceived value and demand.

The versatility of finger joints extends beyond traditional woodworking. With the rise of CNC (Computer Numerical Control) machines, woodworkers can create intricate designs and patterns with unmatched precision. This technology allows for mass production of finger-jointed components while maintaining the quality and strength associated with hand-crafted pieces. As technology evolves, finger joints remain a fundamental technique that merges the old with the new, proving that classic methods can still hold relevance in modern woodworking.

Moreover, finger joints play a role in sustainability within the woodworking industry. By allowing woodworkers to utilize smaller pieces of timber, they help reduce waste and make the most out of every log. This practice is especially beneficial in an age where sustainable sourcing of materials is increasingly important. The ability to join smaller boards into larger ones encourages responsible use of resources while creating stunning pieces of furniture and decor.

As woodworking continues to evolve, the significance of finger joints remains steadfast. Whether in the hands of a seasoned artisan or a novice woodworker, these joints offer a reliable and aesthetically pleasing solution for a wide range of projects. Embracing the finger joint technique not only enhances the structural quality of wooden pieces but also fosters creativity and innovation in design.

In conclusion, finger joints epitomize the blend of art and science in woodworking. They provide durability, stability, and aesthetic appeal, making them a go-to choice for many projects. As artisans continue to push the boundaries of what is possible in woodworking, finger joints will undoubtedly remain a timeless technique that showcases the beauty and resilience of wood. By mastering this method, woodworkers can ensure their creations not only withstand the test of time but also celebrate the craftsmanship that defines the art of woodworking.